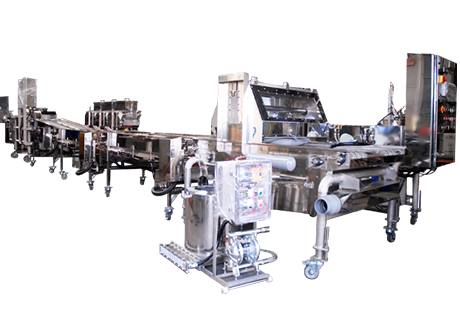

seaweed crisps production line

Product Introduction

SPEC

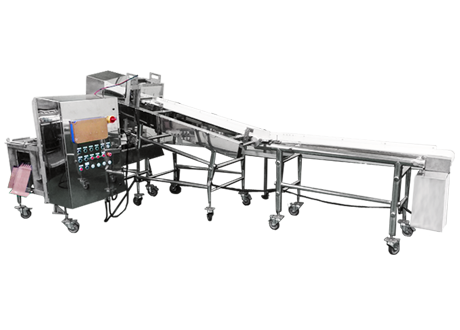

- Model: SA

- Power: 0.75 KW

- Material: SUS304 stainless steel

FEATURE

- Loosen the whole seaweed first, and then put it into the material storage area above the machine. The SA seaweed feeder will automatically pull out the single sheet of seaweed and feed it into the conveyor belt.

- Adjustable suction power

- Adjustable speed

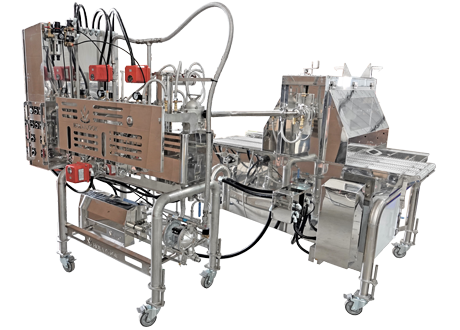

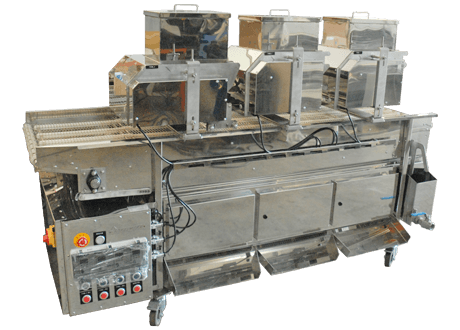

SPEC

- Model: BSC_PSS

- Power: 10 KW

- Material: SUS304 stainless steel

FEATURE

- The syrup is uniformly sprayed onto the seaweed sheet in a fan-shaped manner.

- During the operation, the conveyor belt is immersed in hot water, brushed and dewatered so that the syrup does not repeatedly contaminate the food.

- The machine is equipped with two syrup sealed tanks, which can withstand the pressure within 7 kg. The syrup is delivered by pressure without emulsification of syrup.

- The excess syrup is concentrated in the mechanical retainer and can be connected to our automatic syrup recovery system.

- The syrup pipe is double pipe, which can keep the temperature of the syrup

SPEC

- Model: RD 15

- Machine size (L*W*H): 710*702*710 mm

- Recycling tank: 30 L

- Weight: 65 KG

- Material: SUS304 stainless steel

FEATURE

- Recycle the excess syrup from the syrup sprinkle machine.

- The recycling tank is double jacket design. It maintains the fluidity of the syrup by hot water. Water heating is within this machine itself and temperature can be set freely.

- Collect the excess syrup from Syrup sprinkle machine, filtered through the sieve, and then flowed into the syrup liquid recovery tank.

- The machine equipped with syrup level control system. When the syrup reaches a certain height, the pump is automatically started and sent back to the syrup barrel of the syrup sprinkle machine.

- The control box and motor protection cover are waterproof.

SPEC

- Model: OA2019

- Power: 0.18KW + electric 9KW, air pressure about 4 kg

- Material: SUS304 stainless steel

FEATURE

- It can be used with BSC_PSS automatic syrup sprinkle machine.

- Equipped with automatic mixing function. The storage tank is designed as a double tank. The heating layer can be either filled with heat medium oil or water to maintain the temperature of the syrup and prevent the overburn.

- Heat the mixed syrup to 60-80 ° C and maintain the temperature to ensure the fluidity of the syrup.

- Equipped with waterproof control box and waterproof motor protection cover.

- The heating temperature is adjustable as well as the stirring time

SPEC

- Model: RSC152

- Troughs: 2

- Machine size (L*W*H): 160*60*130 cm

- Spreading width: 25 cm

- Power: 0.56 KW

- Material: SUS304 stainless steel

FEATURE

Put the dried nut into the tanks respectively according to the nut size.

Normally, the biggest nut is in the first tank. Set the speed of the conveyor and each nut holding tank, then the nut spreading job starts.

- This model consists of 2 nut holding tanks.

- Discharge Amount of Each nut holding tank can be set respectively set.

- Suitable for continuous production line. Nuts discharge uninterruptedly.

- Even Spreading and standard discharge amount.

- Suitable for seaweed sandwiching snack.

- The control box is waterproof.

SPEC

- Model: RSC152-X3

- Troughs:3

- Machine size (L*W*H): 160*60*130 cm

- Spreading width: 25 cm

- Power: 0.75 KW

- Material: SUS304 stainless steel

FEATURE

Put the dried nut into the tanks respectively according to the nut size.

Normally, the biggest nut is in the first tank. Set the speed of the conveyor and each nut holding tank, then the nut spreading job starts.

- This model consists of 2 nut holding tanks.

- Discharge Amount of Each nut holding tank can be set respectively set.

- Suitable for continuous production line. Nuts discharge uninterruptedly.

- Even Spreading and standard discharge amount.

- Suitable for seaweed sandwiching snack.

- The control box is waterproof.

SPEC

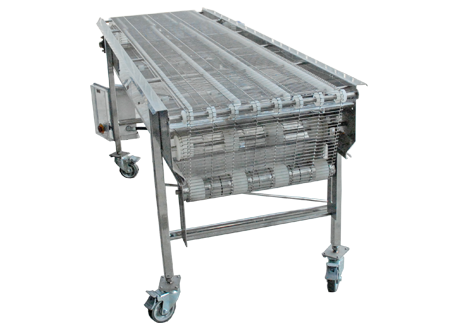

- Model:CV

- Power:0.2 KW

- Machine size (L*W*H): tailor-made

- Material: SUS304 stainless steel

FEATURE

- Conveyor speed is adjustable.

- Equipped with waterproof control box and waterproof motor protection cover.

- Height adjuster is 8 cm

- Deliver food in parallel

- The belt pulley is small, which is good for sticky seaweed chip detach from the conveyor belt.

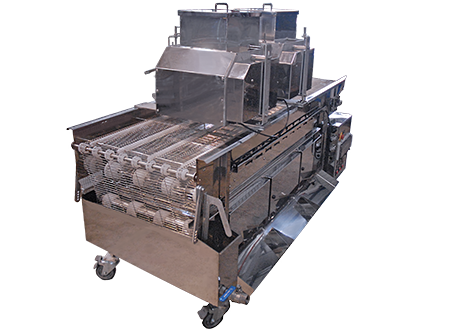

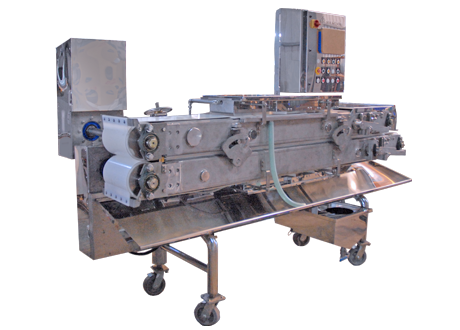

SPEC

- Model: FM1500

- Machine size (L*W*H): 2500*870*2006 mm

- Power: 7 KW

- Weight: 1250 KG

- Material: SUS304 stainless steel

FEATURE

- The seaweed chips that have been full up nuts are automatically pressed to make the chips smoother and stick firmly.

- Conveyor is food grade belt. The belt return is washed in hot water and wiped.

- Press strength can be fine-tuned.

- The whole machine can be water washed.

- The control box and motor protection cover are waterproof.

- The conveyor speed is adjustable.

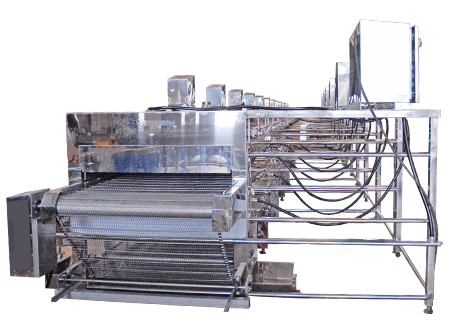

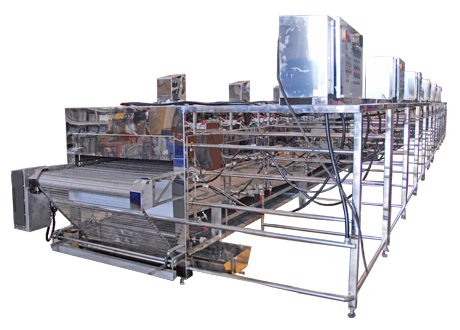

SPEC

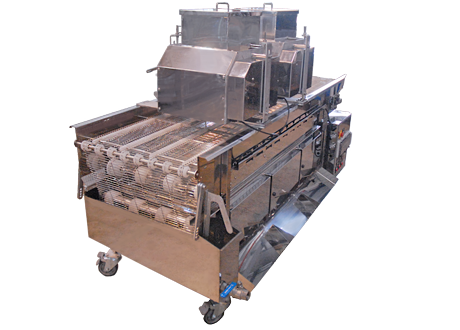

- Model: EO669

- Machine size (L*W*H): 10000*2100*1700 mm

- Effective baking size (L*W): 9000*660

- Power: 90 KW

- Material: SUS304 stainless steel

FEATURE

- The far-infrared electric heating tube is used as a heater, and the output current isstabilized by the SCR.

- All infrared ray electro-thermal tube are placed above the conveyor belt.

- Each district's electric heating is independent switch and temperature control.

- The conveyor speed is adjustable.

- Automatic temperature adjustment.

- The rang of baking time is 1~5 minute.

- Tunnel Oven inside can be water washed!!.

- Specially equipped with Mesh belt soaking water device.

SPEC

- Model: CUTTER-L

- Dimension (L*W*H): 2000*600*1250 mm

- Power: 1.5 KW

- Material: SUS304 stainless steel

FEATURE

- Configure two workstations.

- Cut the seaweed slices in the middle and cut them into strips.

- Equipped with waterproof box and waterproof motor protection cover.

- The cut strip or cut size can be customized before ordering.

- The input speed can be control by frequency converter.

- With high and low adjustment, 360 degrees and 4 brake wheel.